Factory Price 12 Box Pan Brake - Aluminum bending Machine And Sheet Metal Folder 1000E – JDC

Factory Price 12 Box Pan Brake - Aluminum bending Machine And Sheet Metal Folder 1000E – JDC Detail:

Product Description

Superior clamping force along with unquestionable build quality leaves.

Bends all types of sheet metal, aluminium, copper, stainless steel and much greater versatility than conventional sheetmetal benders.

Typical industries: Roofing, Aircraft, General Sheet Metal Fabrication .

Features

Electromagnetic sheetmetal folding machines

To suit: roofing, aircraft, general sheet metal fabrication and training colleges

Electromagnetic clamping

Manual fold

Suitable for all sheetmetal, aluminium, copper and stainless folding

Perfect for deep forming of channels, closed sections and all those hard to do folds

Foot pedal control on MB1250E ~ MB3200E only

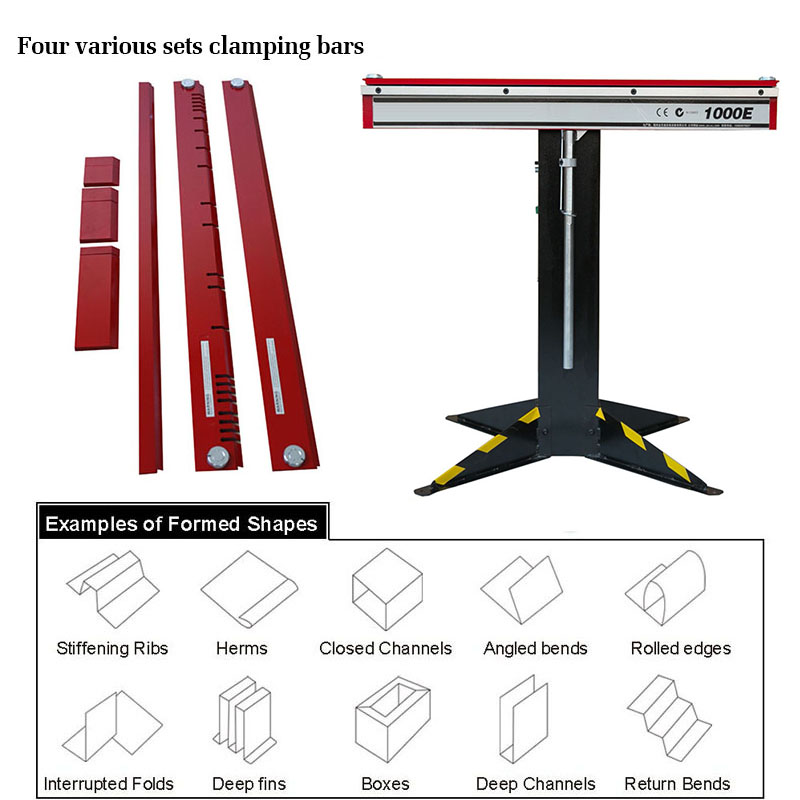

All models supplied with short bar clamp and slotted clamp bar sets

Includes

Calibrated back stop

Full length bar, segmented & thin bar

Storage tray

Operation manual – video available

Technical Data Snap-Shot

1000mm x 1.6mm bending capacity

Superior 4.5 Ton clamping force

Shipping dimensions – 1190mm x 300mm x 350mm = 0.123m2

How it Works

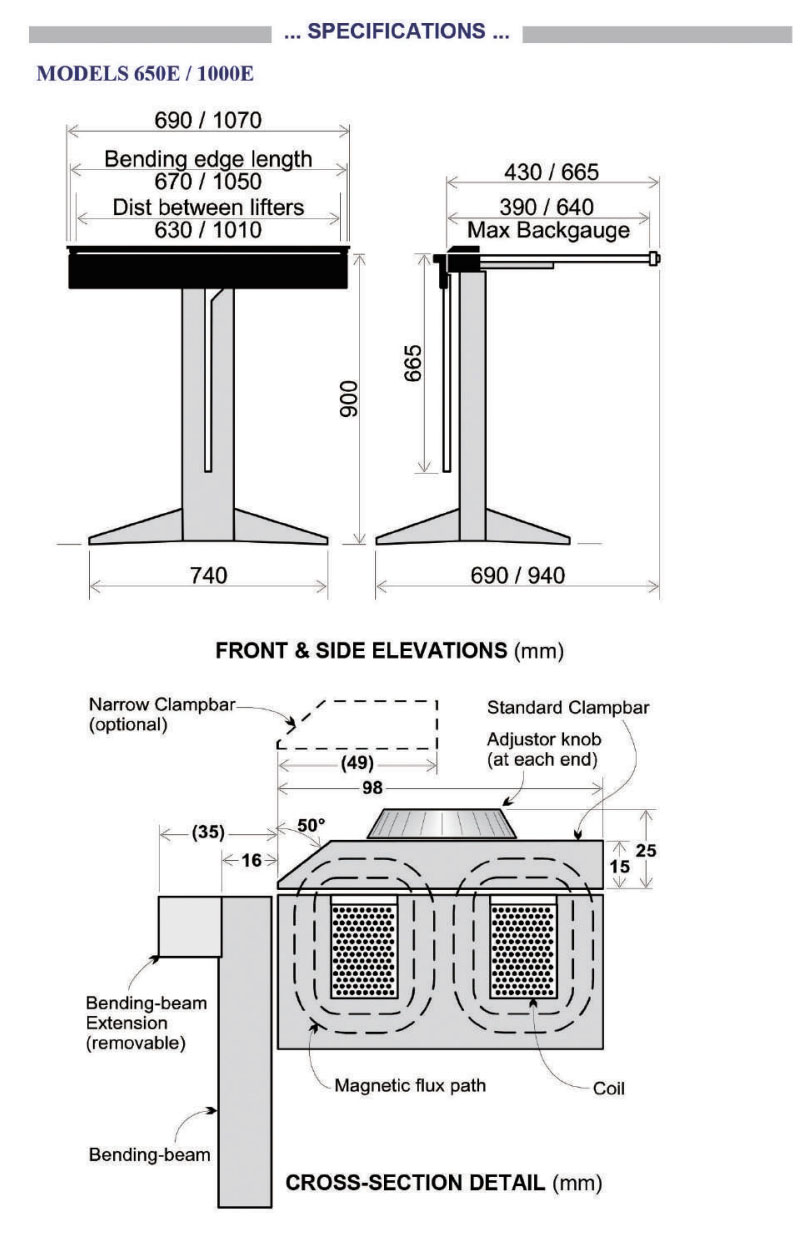

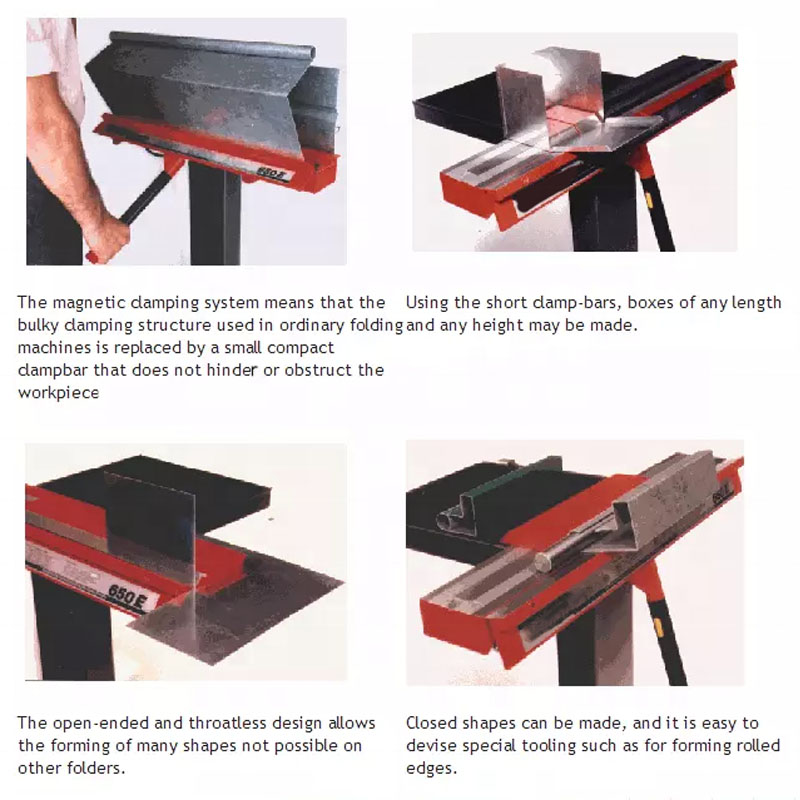

The fundamental principle of the Magnabend™ machine is that it uses electromagnetic, rather than mechanical clamping. The machine is basically a long electromagnet with a steel clamp-bar located above it. In operation, a sheet metal work-piece is clamped between the two by a force of many tonnes. A bend is formed by rotating the bending beam which is mounted on special hinges at the front of the machine. This bends the work-piece around the front edge of the clamp-bar.

Using the machine is simplicity itself; slip the sheet metal work-piece in under the clamp-bar, press the start-button to initiate clamping, pull the handle to form the bend to the desired angle, and then return the handle to automatically release the clamping force. The folded work-piece may now be removed or re-positioned ready for another bend.

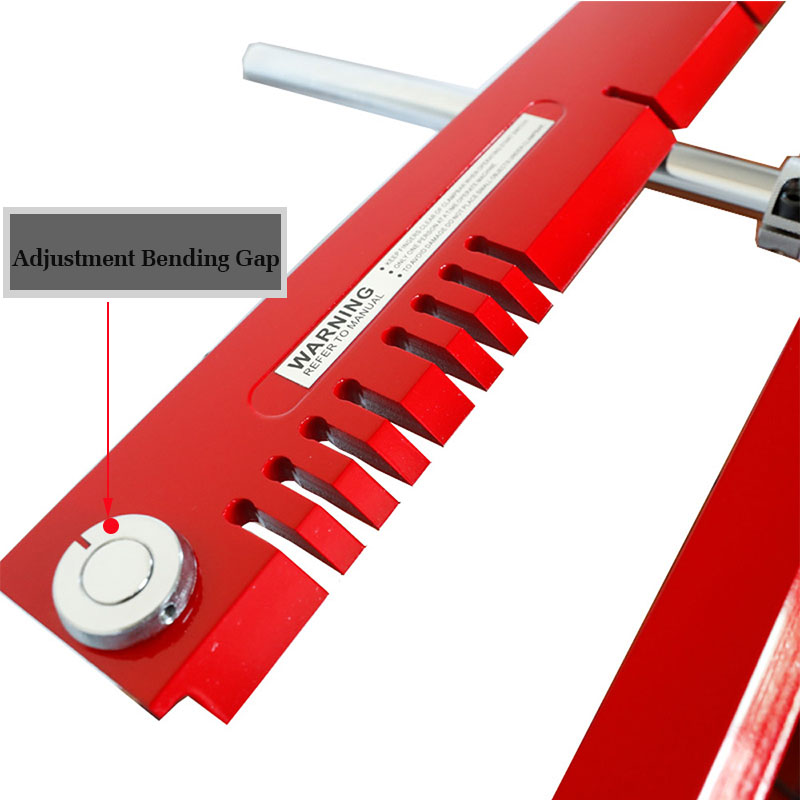

If a large lift is required e.g. to allow the insertion of a previously bent work-piece, the clamp-bar may be manually lifted to any required height. Conveniently located adjusters at each end of the clamp-bar allow easy adjustment of the bend radius produced in work-pieces of various thicknesses. If the rated capacity of the Magnabend™ is exceeded then the clamp-bar simply releases, thus minimising the possibility of damage to the machine. A graduated scale continuously indicates the bend angle.

Magnetic clamping means that bending loads are taken right at the point where they are generated; forces do not have to be transferred to support structures at the ends of the machine. This in turn means that the clamping member does not need any structural bulk and hence can be made much more compact and less hindering. (The thickness of the clamp-bar is determined only by its requirement to carry sufficient magnetic flux and not by structural considerations at all.)

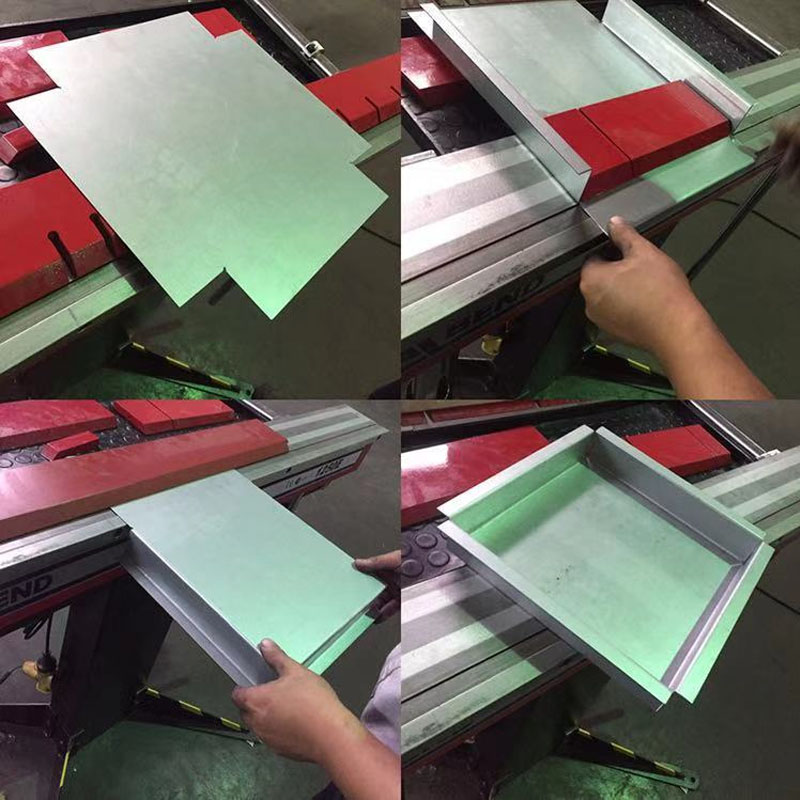

Product detail pictures:

Related Product Guide:

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for Factory Price 12 Box Pan Brake - Aluminum bending Machine And Sheet Metal Folder 1000E – JDC , The product will supply to all over the world, such as: Tajikistan, Liberia, Johannesburg, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!