Electromagneitc sheet metal bending machine Magnabend 1250

Roper Whitney MagnaBend Brake

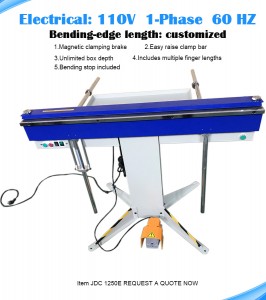

MagnaBend offers performance characteristics no conventional bending brake can match. The unique electromagnetic design of the keeper clamping system allows you to form many complex shapes not possible before. Plus, MagnaBend can handle all regular shapes in light ferrous and non-ferrous sheet metal (up to 4′ wide, 18 ga.) in a simpler, less time consuming and efficient manner.

The rugged simple construction incorporating only one moving part assures low maintenance and versatility for all light duty forming requirements.

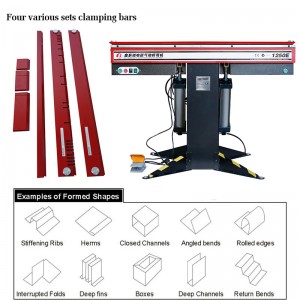

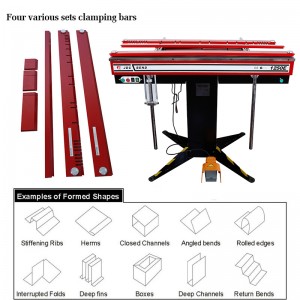

A wide variety of complex shapes can be formed with MagnaBend. These include rolled edges up 330°, partial length bends, closed shapes, unlimited depth for boxes and heavier material bends (up to 10 ga.) in shorter widths.

DESIGN FEATURES ASSURE QUALITY

Simplicity is evident in Magnabend’s electromagnetic design which eliminates a conventional upper beam and more complex finger arrangements. Keepers (clamping members) are simply positioned over the work piece and are clamped in place electromagnetically when the bending beam is raised. Keepers self-adjust for material thickness as the apron moves.

Electromagnetic Design Magnabend – The Magnabend is designed to eliminate the hindrance of an upper beam with the introduction of an elongated electromagnet and keeper system.

Self-Locating – A simple and effective method of locating the full length keeper is achieved by spring-loaded steel locator balls.

Triple Hinge System – Three hinges allow Magnabend to have a lighter bending beam without limiting durability and reliability.

Bend-Angle Gauge – Convenient bend angle gauge features adjustable stop for precise, efficient repeat bends.

Back Gauge – Production efficiency in repeat bends is provided by adjustable back gauge.

Safety Features – The safety button engages a light magnetic force on the keeper. As well as a safety device, this force is a convenient way to stabilize the work piece for precise measurement before you activate full clamping power.

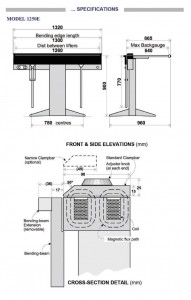

Specifications MBB4181

Maximum bending capacity, mild steel 18 ga / 1.25 mm

Maximum bending length

(Typical bend radius 0.16in/4mm) 49.375″ / 1250 mm

Keepers (Clamping Members)

11 total 3⁄4, 1, 1-3/8, 1-7/8, 2-3/4, 3-3/4, 4-3/4, 6, 12, 21-5/8, and full length 51-1/4″.

19, 25, 35, 48, 70, 95, 120, 152, 30, 550, and full length 1300 mm

Minimum Reverse Bend

With support bar

1-1/2″ / 38 mm

Without support bar 3/4″ /19 mm

Minimum flange bend 1″ / 25 mm

Input voltage 115 volts /1 single phase /60 hertz

Dimensions (LxWxH) 52-1/4 x 27 x 33-1/4″

1330 x 685 x 845 mm